Local Storage seems to be disabled in your browser.

For the best experience on our site, be sure to turn on Local Storage in your browser.

STOCK

The right stock at the right time

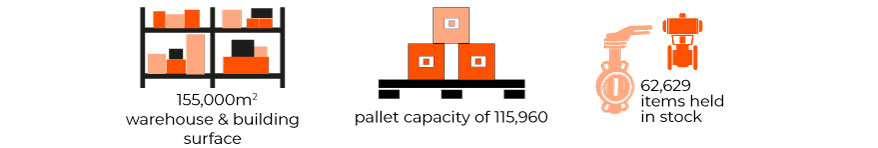

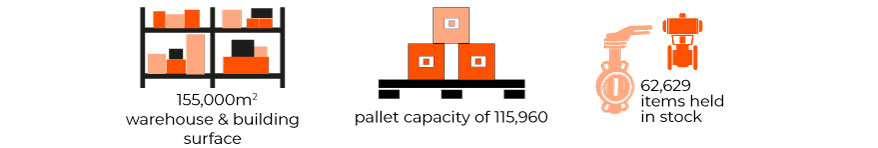

The total volume of our stock is equivalent to 2,702 standard 20-ft containers. We have 155,000m2 of warehouse & building surface spread over several storage facilities, with a capacity of 115,960 pallets. We hold 62,629 items in stock.

Our wide range of products in stock cover all our business areas : valves for industry and building, water supply, HVAC, pumps, garden and pool products. These products are available for immediate delivery. Our stock is in constant development with a search for optimization. We do not hesitate to expand our product range to provide better solutions.

Improving our storage system & supply chain

We are gradually introducing mechanised storage systems to save space and improve the working conditions of our warehouse staff. In 2022, we invested in an order-picking tray system for our industrial fittings range. This is GTP (Goods to Person) equipment that enables high-frequency order picking. In several warehouses, spare parts and smaller items are stored in vertical lift modules. The advantages for the team in charge of the order-picking process are reduced travel time, ergonomics at the workstation and easier stock management.

We are constantly monitoring innovations in the field of storage to find and select the most suitable storage systems for each of our activities.

In order to improve our supply chain, we have a tailor-made tool for optimising our supplies, ThermAppro. Deployed since 2021, this decision support tool for our purchasers is continuously being improved to become more powerful. It is based on machine Learning and artificial intelligence technology.

Warehouse team safety

To ensure a high safety level at our logistic team, we have put in place concrete actions such as:

- The choice to own all our handling equipment, regularly maintained

- The training of all our warehouse workers in safe driving and gestures and postures

- The safety equipment (specific high picking level handling equipment, new safety knifes)

We pay attention to the quality of the floors to limit vibrations, the cleanliness, the proper functioning of forklifts and to lighting inside the buildings.