Local Storage seems to be disabled in your browser.

For the best experience on our site, be sure to turn on Local Storage in your browser.

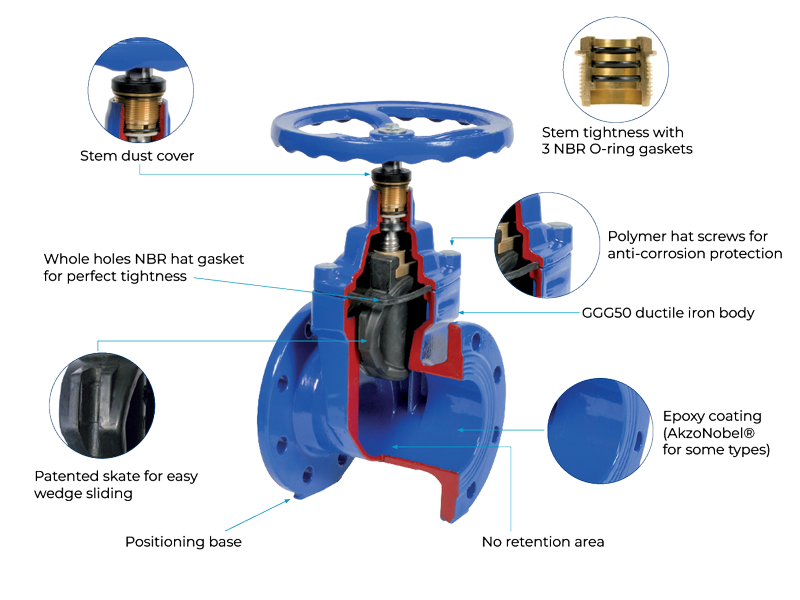

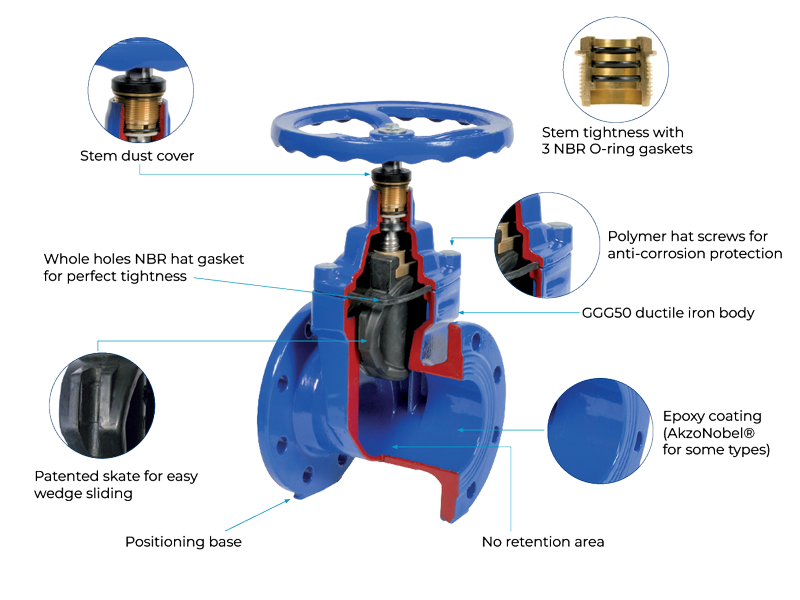

Resilient seated gate valves

The Resilient seated gate valves are designed to ensure long-term reliability and optimum performance in water distribution networks. Built according to EN 1074-2 and pressure-tested to EN 12266-1 (Rate A), these valves guarantee exceptional tightness and durability under demanding service conditions.

Key Advantages:

-

Full Bore Design – Ensures maximum hydraulic efficiency with minimal head loss.

-

Resilient EPDM-Coated Wedge – Offers a secure, flexible seal and silent operation, ensuring durability in a range of water distribution applications.

-

High-Grade Ductile Iron Construction (EN-GJS-500-7) – Provides excellent mechanical resistance and long service life.

-

Stainless Steel Non-Rising Stem (AISI 420) – Ensures durability, low maintenance, and smooth operation over time.

-

Interchangeable Sealing Components – From DN80 to DN1000, the stem gasket can be replaced without shutting down the line.

-

GSK-Certified AkzoNobel(r) Epoxy Coating (RAL 5005, 250 μm) – Protects against corrosion and abrasion for long-term reliability. Only for types 181, 191 and 185.

-

No Retention Zones – Designed to avoid stagnation and contamination in the system.

- Face-to-face - EN 558 series 14 or EN 558 series 15

Applications - Water supply & distribution network

This resilient seated gate valves are particularly suited for:

-

General and industrial water distribution

-

Pumping stations

-

Irrigation and treatment networks

-

Industrial process water

-

Potable water distribution networks - only for types 181, 191 and 185

Our Resilient seated gate valves combine durability, flexibility, and reliability. With its full-bore design, maintenance-friendly features, and corrosion protection, it represents a cost-effective, high-performance solution for water control systems. For potable water networks, choose models 181 or 191 for certified compliance.

Ease of Operation

Available with either clockwise-to-close (CTC) or anticlockwise-to-close (ATC) handwheel operation depending on the valve model, and with options for handwheel, square operating nut, or gearbox actuation, these valves offer exceptional flexibility for a wide range of installation environments. Optional stem extensions and T-keys ensure convenient operation even in underground or remote access locations.